- 8 Posts

- 20 Comments

5·4 months ago

5·4 months agoMasochism, paranoia.

Another vote for Debian, and I’ll suggest you go ahead and install Jellyfin directly rather than messing with Docker.

https://jellyfin.org/downloads/server

I’d been running JF under Docker on my NAS, but when I moved to a new server I decided to just install it directly and it hasn’t been any problem at all. You’ll get a notification when it needs to be updated and it’s just a few clicks to do so. You won’t have to fight with Docker to get hardware acceleration working - which isn’t to say it won’t be a PITA, but it’s one less layer of complication.

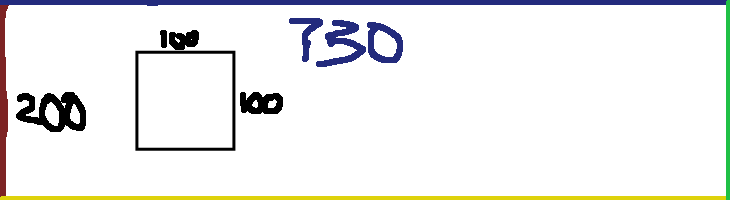

Unless you’re going the hand tool purist route, the table saw is IMO the central tool in the shop. It can rip, cross-cut, and cut joinery like dados and tenons. So you want a good one with a solid fence that won’t frustrate you. I haven’t been in the market for one in a while, so my suggestions will be out of date, but I’m sure others here can help you.

When you’re starting out you’ll probably be buying your wood S4S: surfaced four sides, so it’s smooth and pretty much ready to go. This is how all the wood at the big-box hardware stores comes. Wood from specialty dealers will come rough, and you can surface it yourself with the right tools ($$$) or have them do it for you for a fee ($).

It’s probably best to start with a project in mind, even if it’s shop shelving or something that doesn’t have to be heirloom-quality.

1·5 months ago

1·5 months agoVery elegant! How did you cut the tapers on the legs? There doesn’t seem to be a great way to do it. I’d use the table saw with a custom jig probably.

Better light outside and the patio was a mess.

Thank you! It was made specifically for a Fender P bass, which is not particularly delicate. I have another one with a different design that I made for my acoustic, but that stand is more of a prototype made out of pine and not as impressive.

I do like the idea of moving the ‘head’ forward so it cradles the neck. I only just had enough stock to make this (well, without cutting into some bigger, nicer boards) so I didn’t have a lot of room for features or experimentation.

It would be improved by some googly eyes.

But then, what wouldn’t?

The neighbors love me.

Good call. I have some old suede slippers sitting around that I was going to use for strops - but if there’s enough material I could use them for this. The bass I made it for contacts the spine at its metal neckplate, so that doesn’t need cushioning, but the body does.

I’ve settled on water stones, at least for the moment: 1000, 4000, and 8000 grit. I use a Veritas Mk. 2 sharpening jig. I also have a slow-speed grinder for major reshaping.

I true the stones on a cinder block, but I don’t have to do it very often.

I suggest you take a look at Christopher Schwarz’s ‘Sharpen This’ series from his blog:

https://blog.lostartpress.com/2017/07/11/sharpen-this-part-2-hear-no-evil/

https://blog.lostartpress.com/2017/07/14/sharpen-this-part-3-what-the-is-sharp/

https://blog.lostartpress.com/2017/07/21/sharpen-this-part-4-very-small-rocks/

https://blog.lostartpress.com/2017/07/22/usharpen-this-part-5-the-myth-of-super-sharpness/

https://blog.lostartpress.com/2017/07/23/sharpen-this-part-6-the-bevel-the-devil/

https://blog.lostartpress.com/2017/07/28/sharpen-this-part-7-the-burr-in-the-saddle/

https://blog.lostartpress.com/2017/07/29/sharpen-this-part-8-polish-get-back-to-work/

1·1 year ago

1·1 year agoI can’t recall ever seeing a recipe for a shop-built jointer, though

Maybe not a powered one…

15·1 year ago

15·1 year agoI hate to say it, but it’s probably an acceptable amount of flatness for a jobsite saw. I’m willing to bet their cast iron offerings have better tolerances. You do have the safety features, though.

5·1 year ago

5·1 year agoExcellent information! Yeah, it seemed to me that the cost increase was more than just inflation. As I said elsewhere in the thread, my impression is that their reputation for quality tools has grown, so that must account for some of the extra price. The 2003 catalog is their 20th anniversary. Maybe that means they were too established to be selling under cost to gain market share?

We’ll see if we’re doing the same thing with a Harbor Freight catalog in 20 years.

52·1 year ago

52·1 year agoI’d be surprised if Grizzly’s CEO were making that kind of multiplier vs. the average employee.

I think some of it might be Grizzly gaining legitimacy as a power tool manufacturer. Their earlier reputation (deserved or not) would have been closer to that of Harbor Freight’s today. Now they’re known to be a solid brand and they can charge a little more.

That doesn’t account for the Besseys, which are off the fuckin’ wall.

I just recently got the 17" Grizzly myself. The other choice was the Laguna 1412. I’m sure I’d be happy with either but the decision came down to Grizzly being able to deliver to the house. You need to be prepared to get a ~300lb. crate from the curb into your shop. There’s no guarantee the driver will help you - and if they do you should tip.

You have to consider power, too. The 2HP Grizzly comes wired 220V, so you need service to wherever the saw goes, plus a plug and an outlet from the hardware store.

The blade it comes with is almost useless - too high TPI. I’d ordered a 5/8", 6-TPI blade and it came before the saw did, so that’s what I started with.

10·1 year ago

10·1 year agoThat’s a perfectly reasonable question.

Bench planes are used for taking rough lumber and squaring and smoothing it for use. If you only buy wood from the hardware store you’re used to seeing “S4S” or “surfaced four sides” boards, so it’s already been squared and smoothed by machines. If you buy your wood from a specialty wood dealer, it usually comes rough. In both cases it’s usually not really square and straight, so you’ll need some means to remove warp, twist, cupping, etc.

Hand planes are the old-school tool for the job. Longer planes flatten longer boards, and shorter planes are used to smooth and clean up after the rough work from the earlier planes. I’m in danger of just recapitulating this article by Chris Schwarz, so I might as well link the whole thing:

https://www.popularwoodworking.com/wp-content/uploads/CoarseMediumFine.pdf

This is an excellent explanation of which planes you need, what they’re used for, and how to set them up for that use.

1·1 year ago

1·1 year agoThank you - it’s definitely part of the appeal.

3·1 year ago

3·1 year agoThe material cost is so low and so easy to obtain. I did make sure I was getting Douglas Fir, though - not just generic SPF or whitewood or whatever most framing lumber at the big boxes is. In my area Home Depot only carries Douglas Fir in 2x6, 2x10, and 2x12 - all at different stores. Fortunately the one closest to me had 2x10s. And expect to sort through the rack for a clear board. Generally speaking, the wider the board, the clearer it is.

0·1 year ago

0·1 year agoI’ve actually tried this! The problem is that the sandpaper is too thick to bend neatly in that tight a radius. Maybe I could buy raw grit and stick it in the cavity with spray adhesive…

Well that’s a shame. I’m sort of half-assedly using syncthing to backup my photos from my phone to my server, but mostly I rely on immich. I never really got the hang of using syncthing with my phone.